Hacksaw blades are cutting tools used in conjunction with a hacksaw, which is a handheld saw specifically designed for cutting various materials, including metal, plastic, and wood. Hacksaw blades are thin, elongated metal strips with teeth along one edge, allowing for efficient and controlled cutting.

Key features and aspects of hacksaw blades include:

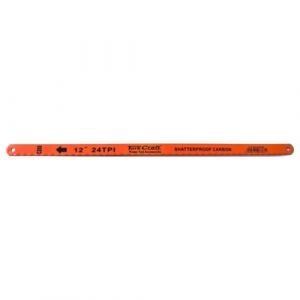

Blade Material: Hacksaw blades are typically made of high-carbon steel or bi-metal construction. High-carbon steel blades are economical and suitable for general-purpose cutting, while bi-metal blades offer enhanced durability and can withstand cutting harder materials.

Teeth Per Inch (TPI): The number of teeth per inch on a hacksaw blade determines its cutting speed and the type of material it is best suited for. Blades with higher TPI provide smoother cuts on thinner materials, while blades with lower TPI are suitable for cutting thicker and tougher materials.

Blade Length: Hacksaw blades come in various lengths, typically ranging from 10 to 12 inches. The length of the blade determines the cutting capacity and the size of the material that can be cut.

Blade Replacement: Hacksaw blades are replaceable, allowing users to easily swap out worn or damaged blades. This makes it convenient to choose the right blade for specific cutting tasks or to replace a dull blade for optimal cutting performance.

Hacksaw blades are widely used in industries such as metalworking, plumbing, construction, and general maintenance. They offer a versatile and precise cutting solution for various materials and can be used for both straight cuts and intricate cutting tasks.

When purchasing hacksaw blades, it’s important to consider the material being cut, the desired cutting speed, and the specific requirements of the cutting task at hand. Selecting the appropriate hacksaw blade ensures efficient cutting and extends the life of the blade.

Showing 29–39 of 39 results

- 1

- 2