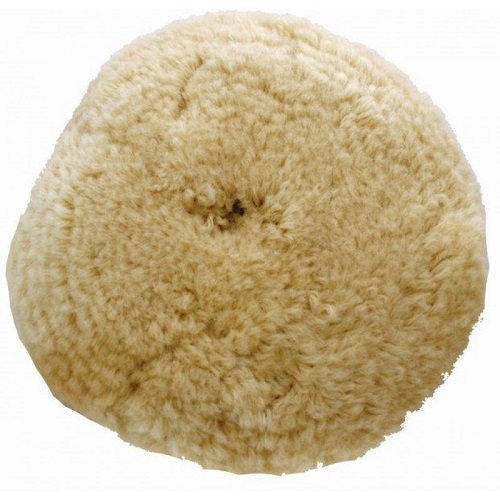

180mm Polishing Bonnet Hook & Loop Concave (SPC00125)

180mm Polishing Bonnet Hook & Loop Concave (SPC00125)

R339.00 Incl. VAT

36 available. Delivery 3-6 working days. Learn more.

Shop Online

and fill your cart

Choose Payflex at checkout

Get approved and

pay 25% today

with your debit

or credit card

Pay the remainder

over 6-weeks.

No interest.

No fees.

Product Description

Diameter: Ø180mm

Use backing pad:

SPC00119

Application:

The polishing wool buff should be used with an automotive polisher.

Different polishes and waxes can be used with the buff. The buff is fastened

onto a rubber backing pad with hook and loop. Make sure the diameter of the polishing buff is

the same as the backing pad’s diameter.

It is necessary to polish a vehicle body panel when:

- The panel has been newly painted with a clear-coat.

- Shallow scratch marks need to be removed.

- The panel has suffered from oxidation.

- Swirl marks and hologram defects need to be removed.

TIP:

The buff is washable after use if the polishing compound is soluble.

hook and loop polishing wool buff range:

| ORDER NO. | DIAMETER | USE BACKING PAD |

| SPC00123 | ø125mm | SPC00120 |

| SPC00125 | ø180mm | SPC00119 |

Recommended polishing compounds to use:

Liquid Shine™

High cut – Features a silicone, wax and filler free polishing

compound to give a high gloss finish on fresh or cured paint. It is capable

of removing P1500 grit sanding marks. It can be used on automotive paints,

marine gel-coats and on composite surfaces.

Liquid Shine™

Fine cut – similar to the High cut polishing compound, but it

is designed for use on a ceramic and scratch resistant clear-coat. It is

capable of removing P2000 scratch marks.

Liquid Shine™

Zero swirl – Very low abrasive for the final step of polishing.

Removes holograms and swirl marks. Use a soft compounding sponge as a final

step

Additional Information

| Brand | Tork Craft |

|---|

Steps to take when polishing a panel:

1. Preparing the panel:

- Sometimes a panel has fine over-spray left from spraying the clear-coat. This needs to be removed by lightly sanding with a fine abrasive paper. All over-spray need to be sanded out up to P1500 grit.

- The panel should be washed when all spray-finishing defects have been removed. Any dirt particles could cause scratch marks when polishing.

- Tight curves and ends of the panel should be masked-off to prevent the effects caused by point pressure. The polisher should always be used on flat surfaces.

2. Applying the polishing compound:

- A five rand coin amount of polishing compound should be applied to the buff. Switch the polisher to it’s lowest speed setting.

- Switch on the polisher and gradually spread the polishing compound over the panel.

- Keep moving the polisher on the panel to have as little amount of pressure and friction.

- The polishing compound will remove the scratch marks caused by the P1500 sand paper and it will bring out an impressive gloss finish.

- Remove the masking from the panels and apply the polishing compound to a microfiber cloth. Hand polish (by moving your hand in a small circular motion) the tight curves and ends in the panels until the same finish is achieved as from the polisher.

3. Wash the panel when finished:

- Wash the panel after polishing to remove any residue from the polishing compound.

You must be logged in to post a review.

Pre-Sale Questions

There are no questions yet.

Ask a question about “180mm Polishing Bonnet Hook & Loop Concave (SPC00125)”

You must be logged in to ask a question.

Reviews

There are no reviews yet.